-

About

Marketing and ServiceBusiness consultation phone number:

Marketing and ServiceBusiness consultation phone number: -

Marketing and ServiceBusiness consultation phone number:

Marketing and ServiceBusiness consultation phone number: -

Application

Marketing and ServiceBusiness consultation phone number:

Marketing and ServiceBusiness consultation phone number: -

Technical support

Marketing and ServiceBusiness consultation phone number:

Marketing and ServiceBusiness consultation phone number: -

Marketing and ServiceBusiness consultation phone number:

Marketing and ServiceBusiness consultation phone number:

Language

The application of optical filters in smartphones

Filtering is an essential step in optical processes such as imaging and recognition, for example:

1. Infrared-cut filter: An optical filter that allows visible light to pass through while blocking or reflecting infrared light. This product is used in imaging cameras for applications including mobile phones, cameras, automotive systems, PCs, tablets, and security surveillance systems.

2. Low-pass filter: Removes moiré patterns and chromatic aberration corrections caused by high-frequency light waves. The product is used in digital cameras, video cameras, and surveillance monitors.

3. Under-display fingerprint filter: Allows green light to pass through while blocking all other wavelengths.

4. Narrowband Filter: A narrowband optical coating is deposited onto a substrate such as glass, enabling high transmission of light within a specific wavelength band while providing deep cutoff for other wavelengths. The filter also ensures minimal spectral shift even under large-angle incidence. This product is used in distance sensors and in the transmit and receive modules of 3D cameras.

In recent years, with the advancement of technologies such as multi-camera systems in mobile phones, periscope telephoto lenses, front-facing 3D structured light, rear-mounted Time-of-Flight (TOF) sensors, under-display fingerprint recognition, and glass back panels, the application of our company’s products in mobile phones has been steadily increasing, leading to a continuous rise in the value per device.

Multi-camera: Driving the Continued Growth of Infrared-Cut Filters

An infrared-cut filter is an optical filter that allows visible light to pass through while blocking infrared light. When light enters a lens and undergoes refraction, visible light and infrared light will be focused onto different image planes: visible light produces a color image, whereas infrared light produces a black-and-white image. Once the image formed by visible light has been properly adjusted, the infrared light will form a virtual image on the same image plane, thereby affecting the color and quality of the overall image.

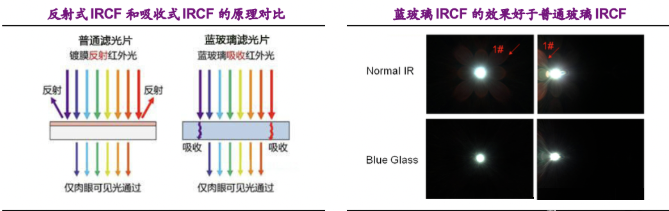

Infrared-cut filters can be further subdivided into two types: reflective filters and absorptive filters. The most critical process in filter manufacturing is coating, which must ensure uniformity and consistency of the coating layer. Coating methods can be broadly categorized into vacuum coating and chemical coating. After coating, these filters can generally block light with wavelengths above 650 nm, thereby meeting basic application requirements.

The IRCF made by coating a blue glass substrate filters infrared light through absorption, effectively blocking wavelengths above 630 nm. In contrast, the IRCF made by coating a conventional glass substrate filters infrared light via reflection; however, the reflected light can easily cause interference and thus delivers a less effective performance compared to the blue-glass-based IRCF.

An important component of 3D cameras—narrowband filters

A narrowband filter is an optical component that allows only light of a specific wavelength to pass through while blocking all other wavelengths. In 3D sensing applications, the transmitting end emits infrared light at a wavelength of 940 nm, and the receiving end needs to filter out all other wavelengths and accept only the 940-nm infrared light; hence, a narrowband filter is required. The transmission band of a narrowband filter is relatively narrow, typically requiring a bandwidth of no more than 5% of the central wavelength.

The thin film of a narrowband filter typically consists of two types of layers—low-refractive-index and high-refractive-index materials—stacked together to form dozens of layers. Any drift in the parameters of individual thin-film layers can affect the overall performance. Moreover, the transmittance of a narrowband filter is highly sensitive to losses in the thin films; thus, it is extremely challenging to fabricate filters with both very high peak transmittance and a narrow full-width at half-maximum (FWHM). There are many different methods for fabricating thin films, including chemical vapor deposition, thermal oxidation, anodization, sol-gel processing, atomic layer deposition (ALD), atomic layer epitaxy (ALE), and magnetron sputtering. The performance of thin films prepared by these various methods can differ significantly.

Under-display fingerprint: Under-display fingerprint technology is rapidly gaining traction, driving increased demand for optical filters.

As the penetration rate of under-display fingerprint recognition solutions continues to rise, demand for optical filters is further increasing.

Previous page

Next page

Previous page

Next page

Quick Navigation

Follow us

Hotline:+86-431-86008533

Human Resources Consulting:+86-431-81785138

Email:lxq@championoptics.com

Email:

Address: No. 1759, Mingxi Road, Beihu Science and Technology Development Zone, Changchun City

Official website

Official WeChat

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页

Sorry,The current column has no content!

You can view other columns or return Home